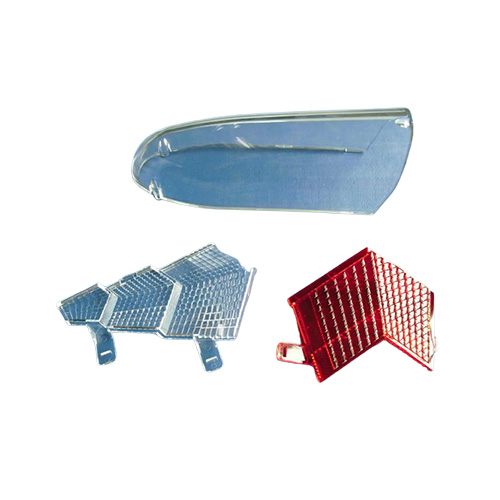

Plastic molded insert parts

Product origin China

Delivery time as customer requested

Supply capacity 100,000pcs/month

Part name: plastic molded insert parts

Material: ABS+PC, PC, PA6+30%GF, etc.

Mould type: 1 or 2 Cavity numbers

Cavity&Core: 1.2344,1.2767, Superplast 400, or customized

Mould base: LKM

hot runner: needle nozzle direct on part, hot tip, tunnel gate

Tolerance 0.05mm

1. Durability: Plastic plug-in products are known for their durability. They are resistant to wear and tear, making them long-lasting and cost-effective.

2. Versatility: Plastic plug-in products can be designed and manufactured in various shapes, sizes, and colors to suit different needs and preferences. They can be easily customized to fit specific requirements.

3. Lightweight: Plastic plug-in products are lightweight, making them easy to handle and transport. This is particularly beneficial for industries that require frequent movement or transportation of goods.

4. Cost-effective: Plastic plug-in products are usually more affordable compared to other materials such as metal or wood. This makes them a cost-effective option for businesses and consumers.

5. Easy installation: Plastic plug-in products are designed for easy installation. They often come with simple mechanisms or connectors, allowing for quick and hassle-free assembly.

6. Resistance to corrosion: Plastic plug-in products are resistant to corrosion, making them suitable for use in humid or wet environments. They do not rust or degrade when exposed to moisture or chemicals.

7. Electrical insulation: Plastic plug-in products can provide electrical insulation, making them safe to use in electrical applications. They can protect against electric shocks and short circuits.

8. Low maintenance: Plastic plug-in products require minimal maintenance. They do not need to be painted or polished, and they are easy to clean with just water and mild detergent.

9. Environmental-friendly: Plastic plug-in products can be made from recycled materials, reducing the demand for new raw materials. They can also be recycled at the end of their lifespan, contributing to a more sustainable and eco-friendly approach.

10. Wide range of applications: Plastic plug-in products can be used in various industries and sectors, including furniture, automotive, electronics, construction, and more. Their versatility and adaptability make them suitable for a wide range of applications.