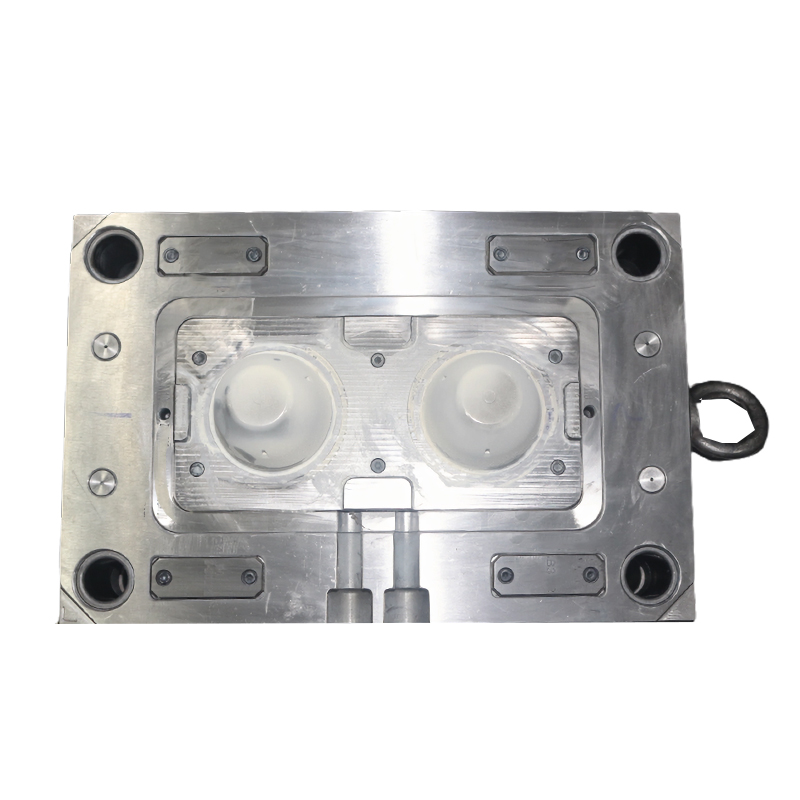

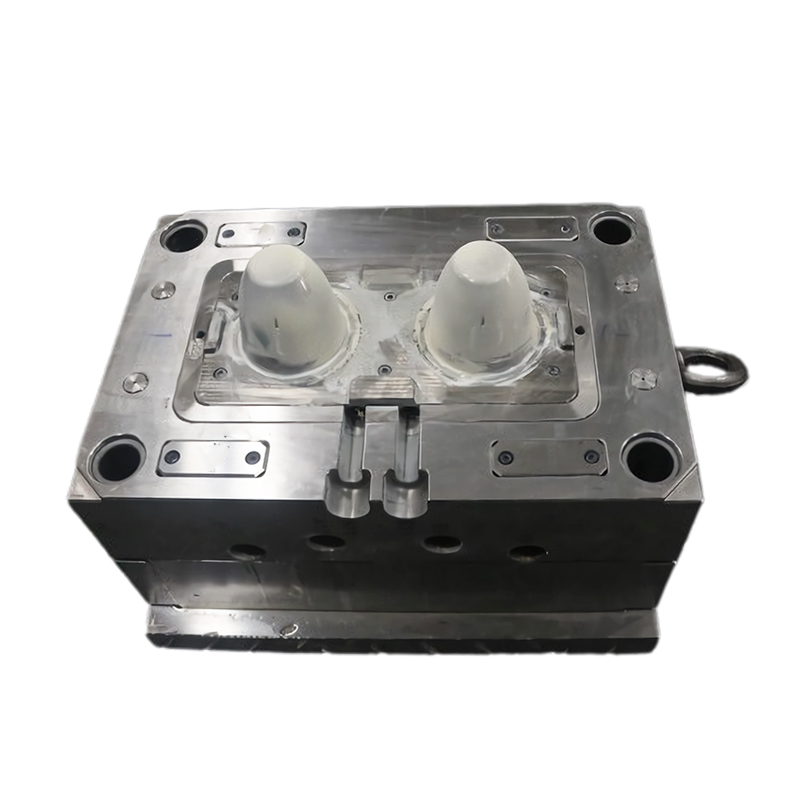

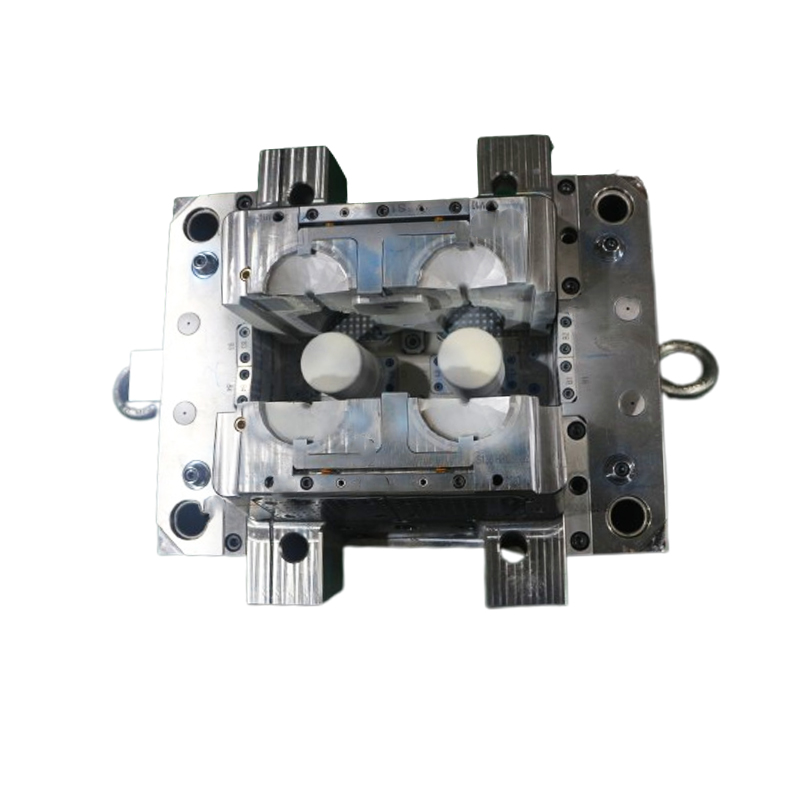

Home Appliances Precision Plastic Injection Mold

Part name: Home Appliances Precision Plastic Injection Mold

Material: P20 (1.2311),P20 (1.2311),S136 (1.2083), NAK80 (P21), 718 (P20+Ni), or customized , etc.

Mould type: 1 or 2 Cavity numbers or customized

Cavity&Core: P20, 718, NAK80, S136, H13, customized, etc.

Mould base: LKM

Hot runner: needle nozzle direct on part, hot tip, etc.

Cold runner:tunnel gate

Tolerance 0.05mm

Wide material selection- ABS, PP, PVC, PC, PE, PA, POM, and more

The steel materials used for Home Appliances Precision Plastic Injection Mold include:

1. P20 (1.2311): This is a low-alloy steel with good toughness and machinability. It is commonly used for medium to large size molds with moderate complexity.

2. H13 (1.2344): This is a hot-work tool steel with excellent heat resistance and high hardness. It is suitable for molds that require high temperature resistance and long tool life.

3. S136 (1.2083): This is a stainless steel with good corrosion resistance and high polishability. It is often used for molds that require high surface finish and dimensional accuracy.

4. NAK80 (P21): This is a pre-hardened steel with good dimensional stability and high polishability. It is suitable for molds that require high precision and mirror-like surface finish.

5. 718 (P20+Ni): This is a modified P20 steel with added nickel for improved toughness and wear resistance.

It is commonly used for molds that require high impact resistance and long tool life.These are just a few examples of the steel materials commonly used for Home Appliances Precision Plastic Injection Mold. The specific choice of steel depends on the requirements of the mold design, such as the complexity of the part, the expected production volume, and the desired surface finish.