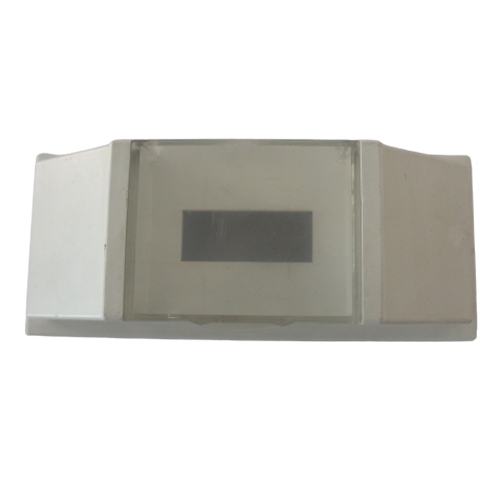

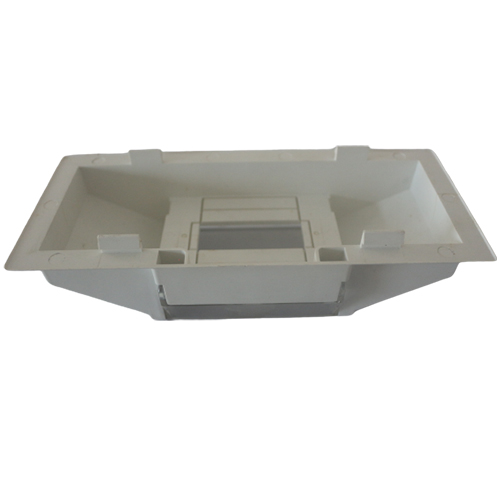

Assembly anti-dust plastic parts

Product origin China

Delivery time as customer requested

Supply capacity 100,000pcs/month

Part name: Assembly anti-dust plastic parts

Material: ABS+PC, PC, PA6+30%GF, etc.

Mould type: 1 or 2 Cavity numbers

Cavity&Core: 1.2344,1.2767, Superplast 400, or customized

Mould base: LKM

Hot runner: needle nozzle direct on part, hot tip, etc.

Cold runner:tunnel gate

Tolerance 0.05mm

Charactristic: Cost-effective, Easy maintainted and replaced, Versatile, Excellent formable

There are several advantages of using assembly dust-proof plastic parts:

1. Protection: Assembly dust-proof plastic parts provide a reliable barrier against dust, dirt, and other contaminants. This helps to protect sensitive components and equipment from damage or malfunction caused by the ingress of foreign particles.

2. Cost-effective: Compared to other materials like metal, assembly dust-proof plastic parts are often more cost-effective. They are usually lightweight, which reduces shipping and handling costs. Additionally, plastic parts can be mass-produced at a lower cost, making them an economical choice for large-scale production.

3. Versatility: Assembly dust-proof plastic parts can be designed and manufactured in various shapes, sizes, and configurations to fit specific applications. They can be easily customized to meet the specific requirements of different industries and products.

4. Durability: High-quality assembly dust-proof plastic parts are durable and long-lasting. They are resistant to wear, corrosion, and impact, ensuring they can withstand harsh operating conditions and provide reliable protection for an extended period.

5. Easy installation: Assembly dust-proof plastic parts are often designed for easy installation and maintenance. They can be easily assembled or disassembled without the need for specialized tools or expertise, saving time and effort during the assembly process.

6. Environmental-friendly: Many assembly dust-proof plastic parts are made from recyclable materials, making them environmentally friendly. Additionally, the production process of plastic parts often requires less energy and resources compared to other materials, contributing to a reduced carbon footprint.

Overall, the use of assembly dust-proof plastic parts offers numerous benefits, including protection, cost-effectiveness, versatility, durability, easy installation, and environmental friendliness.