- Automotive plastic parts

- Special technical injected parts

- Home appliances plastic parts

- Medical plastic parts

- Spare assembled silkscreen parts

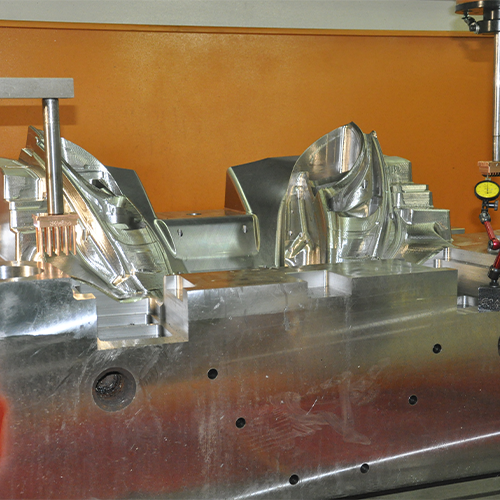

- Automotive Plastic Injection Mold

- Electrical Plastic Injection Mold

- Medical Plastic Injection Mold

- Home Appliances Plastic Injection Mold

- Mold Spare Components

What are the functions of the holes on the injection mold?

Molds are one of the foundations of modern industry, and injection molds are an important branch of molds, a process used to produce plastic components. Plastic products such as automotive parts, medical devices, and consumer electronics can be mass-produced on a large scale through molding.Anyone with some knowledge of injection molds will know that there are plenty of holes around the mold. What are the functions of each hole?

1. The sprue bushing. There are installed on the top of the mold and are used to feed the materials.

2. Water holes. Used for the cooling water transfer and to control the oil temperature.

3. Ejector holes. For the installation of the ejector pins in the demolding system.

4. Guide pin hole. Used to locate the mold base with guide pins.

5. Screw holes.For fixing the mold plate and other accessories, such as slides and lifts.

6. Lifting hole. For the installation of the mold.