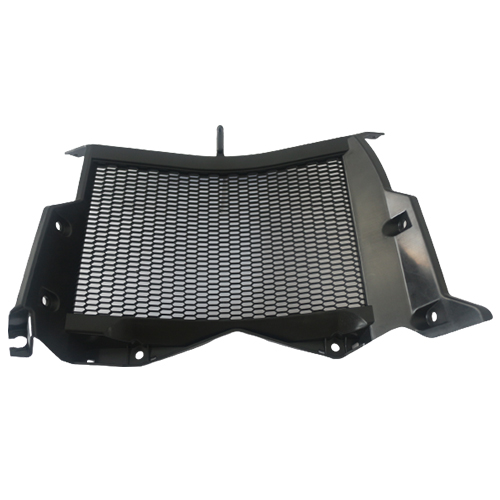

Plastic injection automotive products

Product origin China

Delivery time as customer requested

Supply capacity 100,000pcs/month

Part name: Plastic injection automotive product

Material: ABS+PC, PC, PA6+30%GF, etc.

Mould type: 1 or 2 Cavity numbers

Cavity&Core: 1.2344,1.2767, Superplast 400, or customized

Mould base: LKM

Hot runner: needle nozzle direct on part, hot tip, etc.

Cold runner:tunnel gate

Tolerance 0.05mm

Charactristic: Cost-effective, Easy maintainted and replaced, Versatile, Excellent formable

1.Lightweight: Plastic automotive components are lighter compared to traditional metal products, which helps reduce overall vehicle weight, improve fuel efficiency, and lower emissions.

2.Safety: Plastic automotive products have excellent energy absorption and impact resistance properties, providing protection to occupants during collisions.

3.Durability: Plastic automotive products are highly resistant to wear, corrosion, and weathering, ensuring long-lasting performance even in harsh environments.

4.Design flexibility: Plastic automotive products can be easily molded into various complex shapes and structures, allowing for greater design freedom and customization options.

5.Noise and vibration reduction: Plastic automotive products have good sound absorption and vibration damping properties, enhancing overall driving comfort by reducing noise and vibrations.

6.Energy efficiency and environmental friendliness: Plastic automotive products can be recycled and reused, reducing resource consumption and waste generation, making them more environmentally friendly.