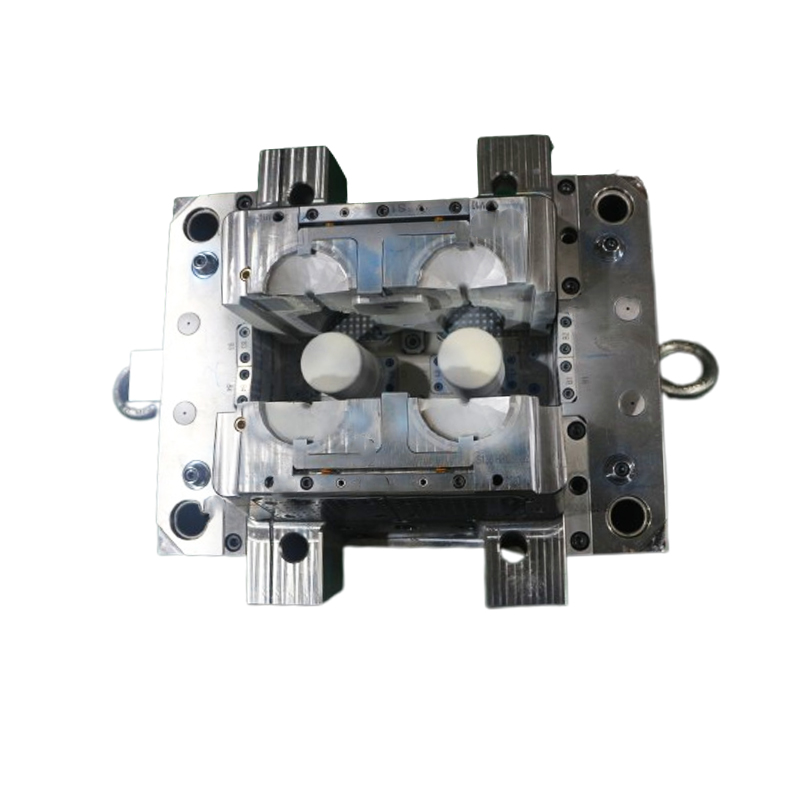

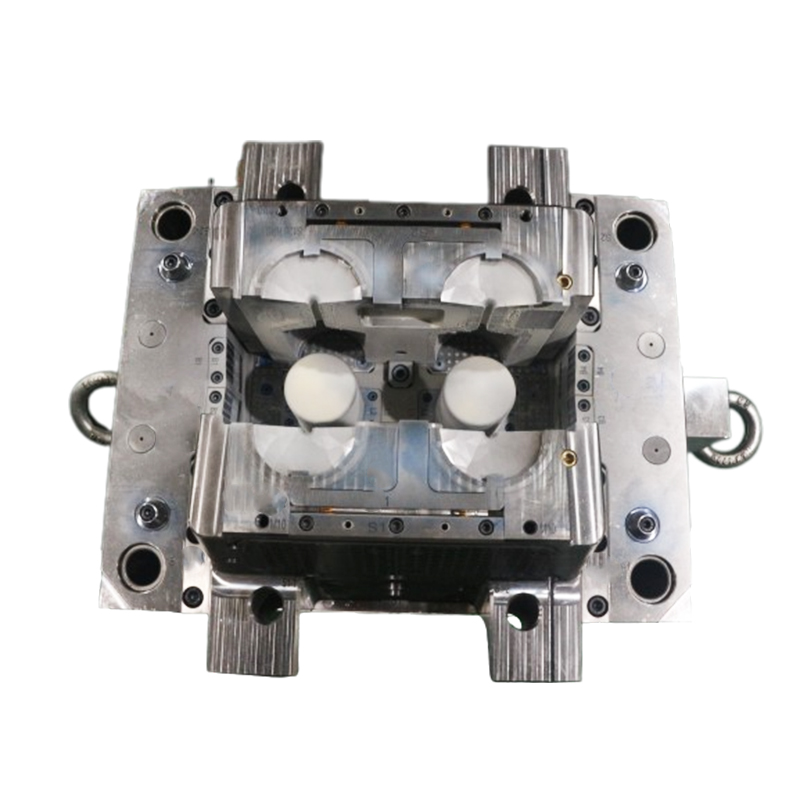

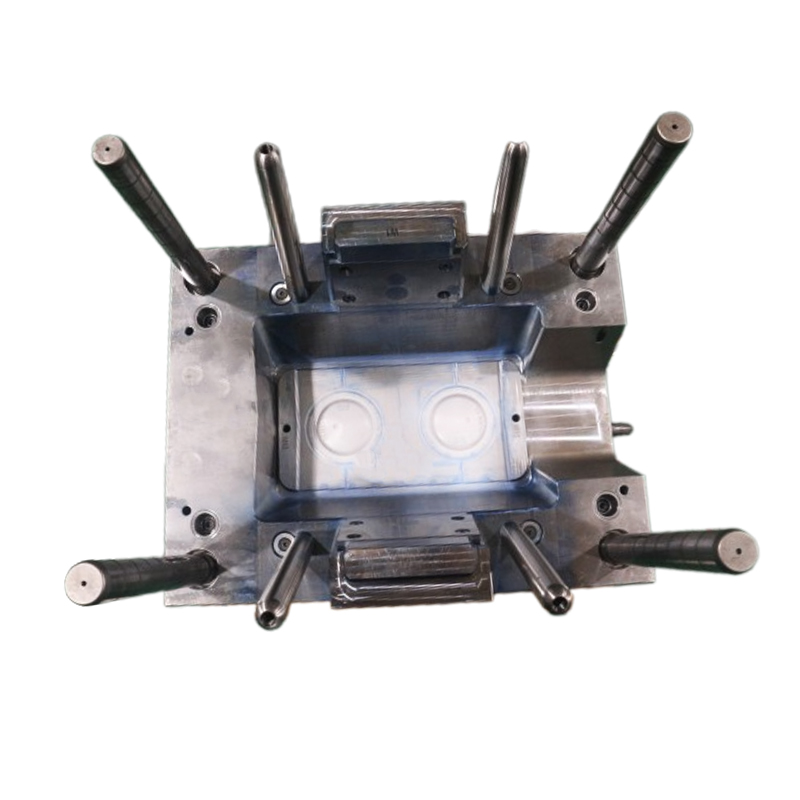

Home Appliances Prototype Rapid Injection Mold

Product origin China

Delivery time as customer requested

Supply capacity 20-40 sets/month

Part name: Home Appliances Prototype Rapid Injection Mold

Material: steel, P20 (1.2311), H13 (1.2344), S136 (1.2083), NAK80 (P21), 718 (1.2738), 420 (1.2083),420 (1.2083) etc.

Mould type: Prototype Rapid mold

Cavity&Core: steel, P20 (1.2311), H13 (1.2344), S136 (1.2083), NAK80 (P21), 718 (1.2738), 420 (1.2083),420 (1.2083) etc.

Mould base: LKM

Hot runner: needle nozzle direct on part, hot tip, etc.

Cold runner:tunnel gate

Tolerance: 0.05mm

Charactristic: Cost-effective, Design flexibility, material selection, Consistency and quality, Time and resource savings

The advantages of rapid injection molding for household appliance prototypes include:

1. Speed: Rapid injection molding allows for the quick production of high-quality prototypes. The entire process, from design to finished prototype, can be completed in a matter of days or weeks, depending on the complexity of the product. This speed enables manufacturers to quickly iterate and refine their designs.

2. Cost-effective: Compared to traditional injection molding methods, rapid injection molding is more cost-effective for producing low-volume prototypes. The use of aluminum or soft steel molds reduces tooling costs, making it an affordable option for small-scale production.

3. Design flexibility: Rapid injection molding offers design flexibility, allowing manufacturers to easily modify and iterate their designs during the prototyping stage. This flexibility enables them to quickly test different design iterations and make necessary adjustments before moving to mass production.

4. High-quality prototypes: Rapid injection molding produces high-quality prototypes that closely resemble the final product. The use of advanced injection molding techniques ensures that the prototypes have excellent surface finish, dimensional accuracy, and material properties, making them suitable for functional testing and market evaluation.

5. Easy scalability: Once the prototype is approved, the same mold can be used for low-volume production or scaled up for mass production without significant modifications. This scalability reduces time and cost for transitioning from prototype to production, allowing manufacturers to bring their products to market faster.

Overall, rapid injection molding for household appliance prototypes offers speed, cost-effectiveness, design flexibility, high-quality prototypes, and easy scalability, making it an ideal choice for manufacturers in the early stages of product development.